Permanent Magnet (PM) Machines

In general, Permanent magnet (PM) machines have a higher efficiency as a result of the passive, PM-based field excitation. PM machines have the highest power density compared with other types of electric machines, which implies that they are lighter and occupy less space for a given power rating.

However, this comes with a loss penalty, even when the machine is inactive, which demands careful balancing of its attributes during the design process.

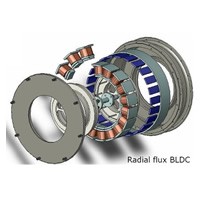

The configuration of a PM machine and the relationship of the rotor to the stator determine the geometry and the shape of the rotating magnetic field. The shape of the back-emf is a fundamental characteristic. PM machines in which the magnetic flux travels in the radial direction are classified as radial-flux machines.

PM machines in which the magnetic flux travels in the axial direction are classified as axial-gap machines. They can have multiple disk or pancake-shaped rotors and stators.

The stator-rotor-stator configuration is typical. The shape of the back-emf of PM machines matches that of the driving currents and can be trapezoidal or sinusoidal. Although both kinds are brushless and synchronous, PM machines with trapezoidal back-emf are often called brushless DC motors (BDCMs),

while PM machines with sinusoidal back-emf are referred to as PM synchronous motors (PMSMs).

The amount of magnet material that is required for a given power rating is a key cost consideration. The cost of magnet material is high compared with the cost of the other materials used in electric machines, and design attributes that minimize the required amount of magnet material are important considerations in machine selection. This demands careful optimisation during the design process in order to meet both design and cost requirements.

PM machines are highly versatile, and used across all areas of industry, but cost is always a consideration, requiring very careful optimisation to realise a commercially viable cost/performance ratio.

Design Services: SDT has many years’ experience of designing all the main categories of PM machines and some less familiar types for a variety of applications. Please see engineering services engineering services >.